Damascus steel manufacturing techniques around the world

The term Damascus, refers to moire fabrics woven in the city of Damascus, not to the swords that were forged there.

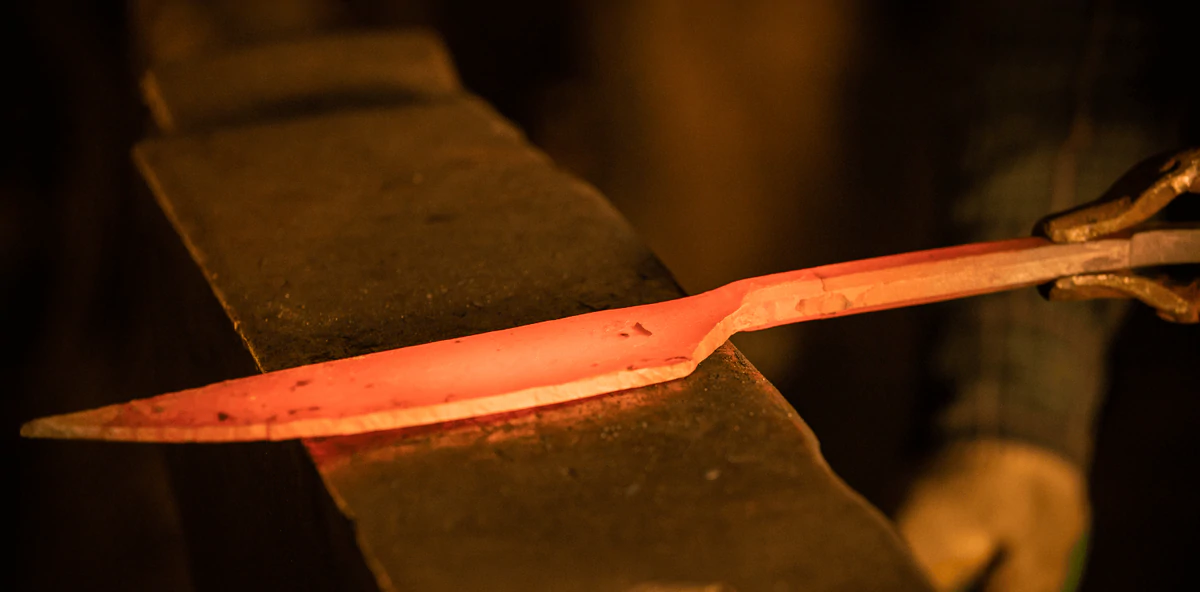

Damascus is a method of refining iron by hammering, folding, and stretching. These operations aim to eliminate impurities from the metal. This results in a composite material with layers of varying homogeneity, typically a combination of iron, steel, or nickel.

This heterogeneous texture provides quite exceptional mechanical qualities, as Damascus steel only partially hardens (since neither iron nor nickel harden completely), thus the metal is not brittle and resists fracture as it diffracts shock waves.

There are several techniques for forging Damascus steel:

The western or Merovingian technique was used by Merovingian blacksmiths; this was actually a form of corrugation, which inexplicably vanished around the end of the 10th century.

The Oriental Damascus or fusion Damascus is the Armenian Damascus par excellence. The wootz is the blacksmith's equivalent of the philosopher's stone, but despite incessant alchemic questing, it seems no one has been able to recreate the complex process driving its formation.

Japanese Damascus is the one found today. It is forged by hammering and stretching. Thousands of sword blades have gradually yielded to a more restrained layer count (a few hundred). Indeed, there's a point at which the texture becomes too dense, and acid testing doesn't yield satisfying aesthetic results.

Aside from the undeniable mechanical qualities of Damascus steel blades, it's worth noting their aesthetic character.

The composite quality of the material conceals countless anamorphic possibilities, which depend on both folding and stretching and deep metalwork (such as sculpting).

Once the Damascus component reaches the desired shape, it's simply dipped in acid, which only darkens the carbon material, thereby revealing the metal's structure.

Stainless Damascus, though highly carbon-based, is made from steel produced using powder technology (very fine grain, which holds up well), since the metal's innate mechanical qualities allow for very hard tempering (up to 63-4 Rockwell) after cryogenic treatment.

Powder Metallurgy

To manufacture metals using powder metallurgy, molten ore is placed in a vacuum chamber where it receives a blast of argon gas, with gas droplets setting the molecules. The ore is then converted into powder.

Depending on the desired steel grade, the different powders are then mixed, heated in a vacuum isostatic oven, and compressed under high pressure (2000 bars).

The resultant steel is virtually non-porous, enabling its use in advanced industries such as aerospace.

In cutlery, steels produced by powder metallurgy make an excellent material for manufacturing carbon-rich stainless Damascus steel. Different patterns with notable aesthetic qualities are achieved depending on the folding and stretching during the Damascus forging process.

This article covers Damascus blades in general and not those sold on this website.

Discover the Art of Sushi: An Exploration of Japanese Flavors